MADE IN EU - how we produce our childrens furnitures

All Children's Furniture www.dannenfelser.eu shown on our information page, gerfertigt except Dressers, here in Europe. This means that the employees in the furniture factory to build itself to European standards and customer requirements, and also think.

This is not always a matter of course. Productions in distant countries do not meet these high standards often only slightly up. This does not mean that there poorer employees work in production, they have but often a different relationship to furniture. While we here in Europe perfect goods expected, almost regardless of the price range, the claim is there another, for a little scratch, for example, is there also accepted for virgin, as the furniture anyway soon traces will have home over time. So that is not the case with our furniture, we produce only within the EU.

We ourselves are in the production process max. integrated possible and spend time directly in production. So we can ensure that only tested Furniture reach our warehouse in Hamburg. Furniture is still made largely by hand. That is for each company so, whether they are small producers or to large chains. This begins with the preparation of the raw material that is naturally prepared for further processing by machine, testing the quality of the wood ansich and the result after surface preparation but is done by the people themselves. Machines can not look into it. Even the custom sawing of wood and other materials such as high-grade E-1 MDF is made by controlled by manual machines.

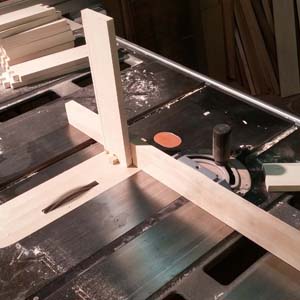

In our factory but called CNC machines are used mostly come. These are robots that automate example our star milling in the loft bed-hanging shelf - and in a perfection that a man can not achieve. but CNC machines also cut wood and - and this is particularly important - Drill the holes automatically in the wood, later the screw takes place in the assembly. For all parts, for example, a bed that is not yet possible, but at least for the most part. For CNC Mschinen one needs qualified personnel, since these are controlled via software and the machines run only what the software tells. You see, we ensure in advance as well as during production ensure that you home as possible achieved only perfect goods. but nevertheless should encounter any errors, we try this immediately and easily fix.

If new furniture should smell once

That can always happen that the new furniture smell, which is independent of the price range. Basically almost smell all new products that knows you best of a new car, where the plastics have to evaporate the leather or other materials nocht. Usually the leaves but after a few weeks back. The reason is usually that the furniture once the paint has dried after the painting operation, immediately in foil and is then packed into the shipping container. There, the parts cook, but the smell can not escape, but only if the furniture will be unpacked in your home. The Gruch is unbedenktlich because all furniture has been painted by the EN 71-3 standard. The transpiring be directly in the factory for capacity reasons not always possible, since once has to start with the production of other furniture and it often fails because of the space available to store the furniture there 1-2 weeks.

Impressions of various production steps of our children's furniture and explanation of the production process of our children's furniture

| First, it comes to a controlled drying process with the aim of achieving the use of humidity of the wood. If that is wood too moist, it may lead to, for example, cracking. The moisture content is usually so with 8-12%, while forest fresh wood has a good 40% humidity. For drying the wood comes to us for Konvektionstrockung in the drying chamber. |

|

| The next step is the further processing in the sawmill. Here the wooden boards are peeled and cut according to the desired level. |

|

| the wood is primed and then several times in several layers painted by professional spray gun Next. Again, there are in the production professional employees who do nothing more than to paint every day. Only in this way also ensures that the paint is applied evenly and lasts binding. Then is followed and ensured by hand with the finest sandpaper that all Spühnebel disappears from the timber and a nice smooth surface. |

|

| Assembly of prototypes and testing the stability, paint and determining what types of screws to be used in compliance with the standards. |

|

|

The finished bed has formed. Now the right packaging is determined, in which special protection is given to the protection of corners. |

|